As a newcomer to the upholstery trade, I have had the great luxury of getting to know folks who’ve been in the business for about as long as I’ve been alive. As many of these upholsterers are starting to slow down their business and ease into retirement, I wanted to learn more about their experiences, thoughts on the trade, and their advice for a new upholsterer such as myself before they decide to lay down the staple gun for good.

For my third installment in this series, I sat down with Dave Kreiter of In-Out Upholstery. Contact Dave at (319) 338-3092 or find out more at davekreiter.com

Dave in front of his tool wall.

Dave is semi-retired and if his is any indication of what the life of a semi-retired upholsterer looks like, then I’m in the right business. I visited Dave in the shop behind his house where he does his upholstery work and where one sees evidence of his many other interests and hobbies: there is a drum set at the entrance, his paintings adorn the walls, and he has at least one of the books he has written on hand. Dave works on furniture for a few hours a day, enough to be a pleasure to work at and to bring in some extra income.

Dave got into the upholstery business in 1972 and like many of the other upholsterers I’ve talked to, he fell into the business through coincidence. The father of the woman Dave was dating at the time was an upholsterer and asked Dave to help him run the shop. This arrangement lasted for about 5-6 months and Dave was able to pick up some of the basics during this time, though he still “didn’t even know how to sew”. Later, a friend approached him about starting an upholstery business together. Though he didn’t feel very experienced, he went for it and together they taught themselves how to recover furniture. After about three years when his friend lost interest, Dave bought him out and continued the business.

For Dave, the draw of furniture upholstery isn’t necessarily a passion for fabric or furniture, but that it allows him to work for himself and make a living and has “always allowed [him] to pursue other hobbies.” Dave strikes me as someone who is a life-long learner and enjoys trying new things; this is evident in his hobbies as well as his upholstery work. Dave has mostly been self-taught and even after more than four decades of experience, he is still learning and trying new upholstering methods. He still gets jobs in “that there is something new about it that [he’s] never seen before” and he continues to experiment with how he does the work.

The sign outside Dave's shop reveals that upholstery is just one of his many interests.

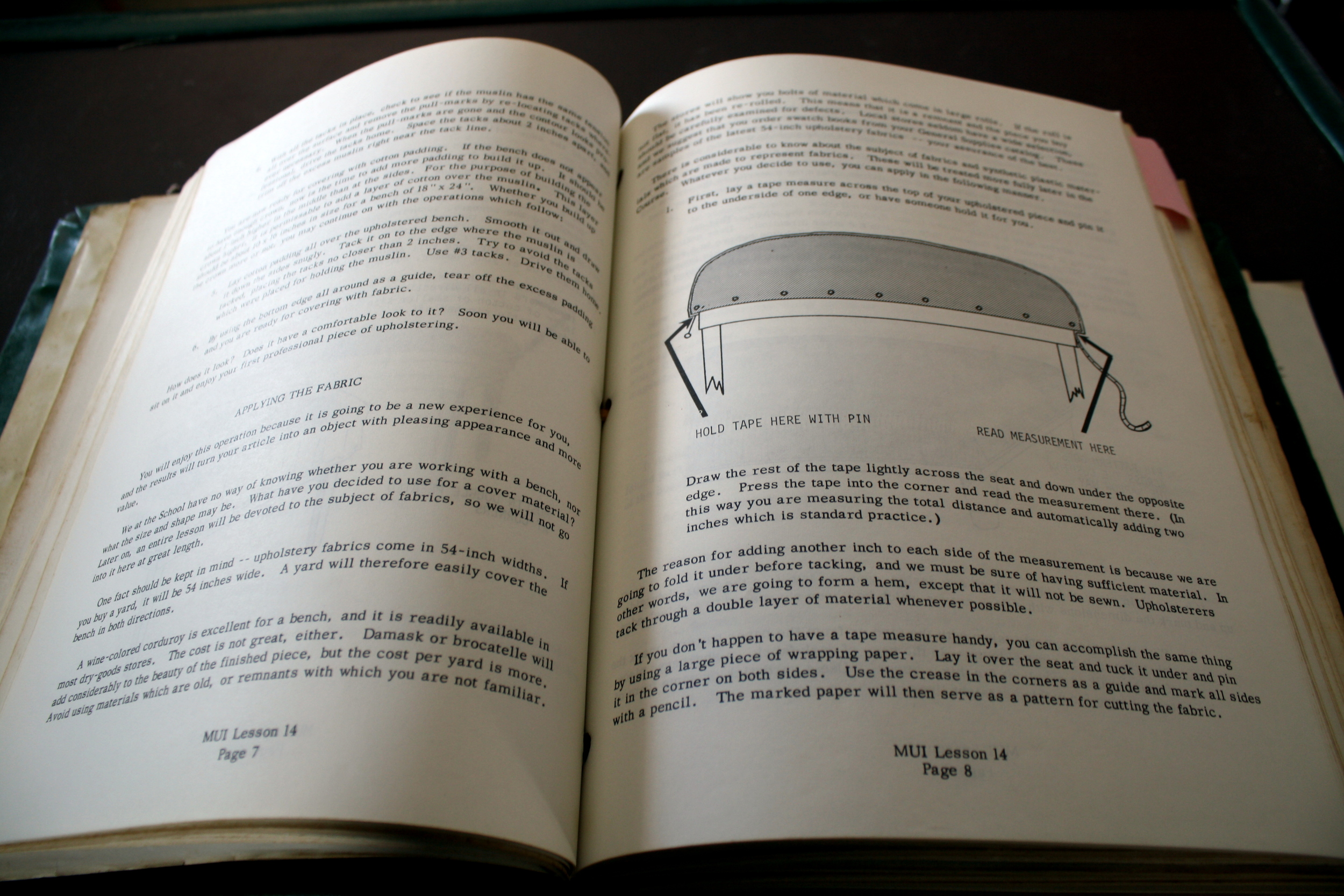

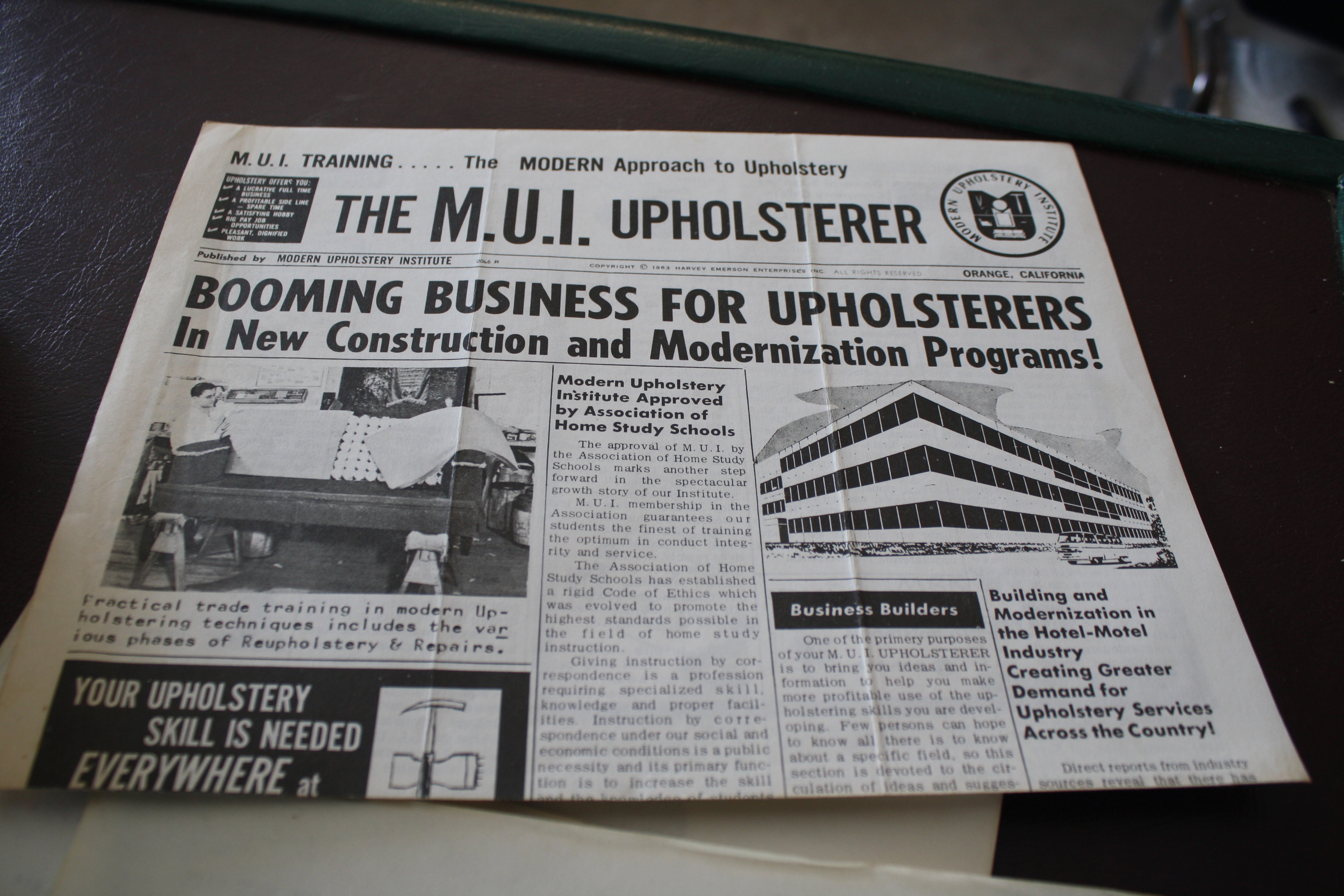

On the topic of the past and future of the business, Dave said that when he started out, he knew an upholsterer who was still “spitting tacks” (referring to a method used before staple guns when an upholsterer would hold tacks in his or her mouth, then ‘spit’ them out one by one onto a magnetic tack hammer and drive the tack into the frame), but other than that move from tacks to staples, little has changed in furniture upholstery. There are of course newer, synthetic materials out there which often make the work easier, but generally the techniques are the same. Looking ahead for the trade, Dave acknowledges that there are some threats in the present and the future. The profession itself has died out to some degree -- where there used to be many upholsterers in this area a few decades ago, now there are just a handful. Additionally, with the prevalence of more cheaply made furniture, its usually more expensive to recover a piece of furniture than to buy new. On the upside, he thinks that many folks are becoming more environmentally-minded and choose to refurbish furniture rather than send it to the dump, saying that “people are thinking twice now about the idea of just throwing something away.”

I often despair about my upholstery skills and how long it takes me to do a seemingly simple job, but Dave’s advice for a new upholsterer has helped me buck up in times of self-doubt. Though “you can learn the techniques really quickly,” building skills is a long game -- it took Dave about five years until he felt that he was experienced enough that the work he was putting out was consistently high quality. For him it just took practice to reach that point -- practice, and not being afraid to reach out: “if you don’t know how to do something, just get help . . .there is nothing wrong with that.”

Working on some chair seats.

When I told Dave about my theory of upholstery as an incubator for essential life lessons, he was right there with me and had some poignant observations and lessons of his own to contribute. Among them, the recognition that “no matter how long you do it, you’re going to make mistakes . . . one life lesson its really taught me is that there is nothing wrong with failure because mistakes are just part of it.” Fortunately, in upholstery mistakes can be taken out and corrected; I often repeat to myself the adage “if at first you don’t succeed, try, try again” (and sometimes it does take a few tries). Thats why focus and patience are also big lessons I take from upholstery, as does Dave saying that “you can’t do this job if you’re not patient.” Dave also helped me see that, like most things in life, learning this business is a process. One has to view even the shaky early stages as part of the road to a larger goal and as opportunities to learn more and to experiment. Ultimately, if you are generous to yourself and give yourself the space and time to develop, all while being present in the process, you will not only reach your goal, but exceed it.